Suzuki Develops New Technology for Corrosion-Resistant Anodising Treatment on Outboard Motor Engine Components

– Approximately 50% Reduction in CO2 Emissions Compared to Conventional Treatment –

Suzuki Motor Corporation has developed a new technology that applies a corrosion-resistant anodizing treatment which can withstand high temperatures to the engine components of outboard motors, including the cylinder block, cylinder head, and crankcase. The treatment has been adopted to some specifications of the DF140B from August 2024, a first for mass-production models*1. It will progressively be adopted to other models’ specifications as well.

Outboard motors pump up large amounts of water such as seawater to cool the engine. This makes corrosion prevention treatments for the cooling water passages vital. The technology developed by Suzuki improves corrosion resistance against seawater by the uniformly applied anodizing treatment to the engine components that come in contact with the cooling water. Additionally, this new technology contributes to carbon neutrality by reducing CO2 emissions by approximately 50%, compared to conventional corrosion resistance surface treatment processes.

-

Key Features of the New Technology

- Improved Corrosion Resistance through Anodizing Treatment

Anodising treatment is a process that involves immersing aluminium in an electrolytic solution and passing an electric current through it to create a porous layer on the surface. Corrosion resistance is enhanced by the formation of an aluminium oxide coating. By innovating the immersion process to prevent air pockets, we can now uniformly treat the complex shapes of cooling water passages.

- Enhanced Heat Resistance through Low-Temperature Sealing Treatment with Metal Hydrates

The coating generated by anodizing can crack when exposed to very high temperatures, leading to reduced corrosion resistance, making it unsuitable for engine components that can reach extreme temperatures. By employing a low-temperature sealing treatment using metal hydrates to close the fine pores on the surface, we have established a sealing method for anodized surfaces that maintains corrosion resistance even when exposed to temperatures of 300 degrees Celsius. This method is the first of its kind to be adopted for mass-produced outboard motor engine components. *1

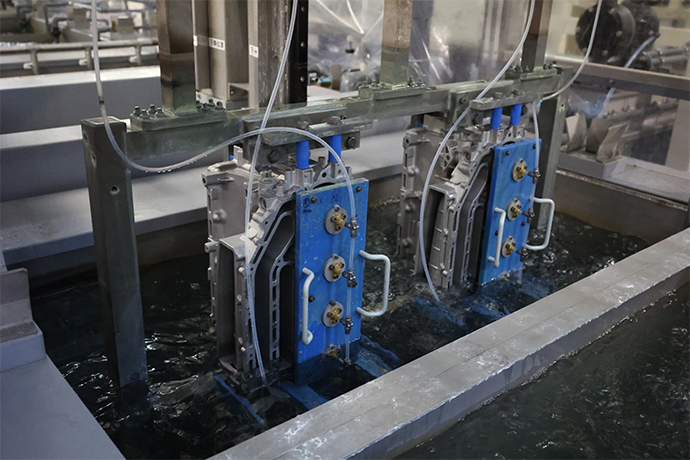

- Sealing Technology to Prevent the Cast Iron Sleeve from Contacting Electrolytic Solution

The cast iron sleeve integrated into the cylinder block can suffer from pitting due to electrolysis if it comes into contact with the electrolytic solution, resulting in defective products. Therefore, we have developed a sealing technology using a dedicated jig to prevent the cast iron sleeve from contacting the electrolytic solution. This technology is currently under patent application. *2

- Contribution to Carbon Neutrality through CO2 Reduction during Manufacturing

Conventional surface treatments to enhance the corrosion resistance of cooling water passages involved chemical treatment followed by painting. By switching to anodizing treatment, we can eliminate this process. This change removes the need for energy consumption associated with drying and baking the paint, resulting in approximately a 50% reduction in CO2 emissions compared to conventional treatment methods.

*1 Based on Suzuki research

*2 As of February 2025