Sydney-based naval architect is designing and testing boats required to perform diverse roles using High Density Polyethylene

Few boat-building materials can offer the ability to withstand high impact usage and provide a smooth, flexible ride at high speed, High-Density Polyethylene (HDPE) is emerging as a serious contender.

Sydney, Australia-based naval architects One2three has been designing boats in HDPE for more than a decade but the material is only lately attracting broader market attention for defence and small workboat applications.

For high speed patrol and enforcement craft it offers a ride that is smoother than aluminium; in workboat applications HDPE withstands everyday impacts and contact better than metal, making it suitable for all kinds of craft in demanding environments.

One2three’s Senior Naval Architect Mike Hodgkinson says that demand for military and tactical rigid inflatables and rugged workboats from enforcement agencies and local authorities in Australia has increased significantly.

“HDPE is not that well known, but it’s not new either. We’re really seeing it getting traction now, particularly in the defence market,” he says. Among its attractions for this sector are reduced radar signature and no magnetic or electronic signatures, making it a compelling choice for next generation defence tactical assault and mine-countermeasure vessels.

The company has recently designed three 12.5m patrol craft built by Tasmania’s Sentinel Boats, each capable of speeds above 40 knots; he says these designs are helping to push the limits of HDPE capability.

“HDPE is second to none in terms of durability and suitability for extreme operating environments. The average person might not be able to see the difference but compared to aluminium or steel, you can make boats that are virtually unsinkable.,” he adds.

One2three has used SSI’s ShipConstructor software since the company was founded and uses the same program for HDPE projects, creating a 3D model for all flat or curved plates and stiffeners. After reviewing design components in Navisworks software, the resulting components are nested, cut and assembled just like aluminium or steel.

“Creating a model for an HDPE vessel means some additional design focus on rebates and intersections of the structure, which is thicker than aluminium,” explains Naval Architect Hamish Knox. “All the data the builder needs is put into the nesting file and exported using ShipConstructor for the downstream process.”

HDPE is a material with homogenous properties but attention has to be paid to importing accurate design inputs which take account of trim and heel performance.

“Building a lightweight high speed boat has strict performance requirements and weight limits as they are designed for lift-out alongside a larger ship,” explains Mike. “Being able to model in 3D using ShipConstructor enables us to get accurate weights and a level of comfort so we can push the design envelope in terms of competing for tenders.”

A recent contract for a New Zealand-built boat built by Sentinel in Tasmania came out within 1% of design estimates while a larger catamaran design was 0.1% away from predicted weight when constructed.

The choice of steel or HDPE may come down to the buyer or builder’s preference but Mike says they are increasingly interested in the shock and vibration absorption properties of HDPE.

The increasing application of HDPE in the defence sector is also attracting interest from classification societies which are adapting their rule sets to this new vessel type. Being able to provide class certification of the design is a useful value-add to government buyers for class approval of larger vessels.

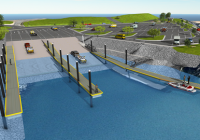

One2three has also used HDPE for small workboats used in marine rescue and as harbour craft. The chief characteristic here is not speed but the ability to withstand impacts every day and still perform as designed.

“HDPE works well in any hardworking industrial application whether that’s emergency rescue, port authorities or fish farms, these ships literally take a beating every day,” adds Hamish.

Building in HDPE means higher initial capex costs than aluminium – though with arguably better performance in terms of flexibility and impact resistance. Hamish adds that the “through-life cost of HDPE is lower than aluminium because it’s so resilient, we’ve won competitive tenders on that basis.”

“In terms of vessel size, 12m is where the limit for HDPE is right now but it’s creeping up, we’re looking at 15m in the right usage profile and there may be a potential to go bigger,” says Mike.

For more information, visit the One2three website HERE