Article by Hans Buitelaar, Metstrade

Yard applies new technology to create low-footprint lease fleet

Magma sourced fibres and organic aramid fibres that come together in a twisted yarn define the next stage in sustainable composite technology. Belgian fibre manufacturer Isomatex has developed and patented this fibre in co-operation with Airbus. French yard Innovation Yachts is a first user to demonstrate the strength and recyclability of the fibres in boat construction.

“The key to creating a consistent quality of yarns from different mineral fibres, in which volcanic fibre and other organic materials are combined, is in ensuring a very stable temperature throughout the oven in which the materials are blended,” Norbert Sedlacek of Innovation Yachts explains. Without going deep into the chemical procedures of creating mineral fibres from different materials like rock, ores and plant based origins, the commitment of Sedlacek to creating sustainable yachts remains obvious. His shipyard in the French town of Vairé, near ocean sailors’ hub Les Sables d’Olonne, is dedicated to developing and building yachts from non-fossil resources which are completely recyclable. This yard applies the Filava fibre from Isomatex and in their continuous search for improvement of reduction of their environmental footprint, the founders of the yard are involved with the research into development of better, stronger, more impact resistant and easier recyclable materials. The yacht builders, together with the fibre manufacturer, claim that Filava results in composites that are stronger, have higher impact absorbtion, can resist higher temperatures, are more resistant to water ingress and UV radiation and cause no allergic reactions as compared to conventional carbon fibre epoxy composites.

Mineral Fibre early adapters

Innovation Yachts created the IY Open 16 Fipofix sailboat that crossed the Atlantic Ocean two times. This boat of only 4.9 metres in length was the first demonstrator of the Filava volcanic fibre for composites in yacht building in 2012. After establishing their yard Innovation Yachts in 2016, the IY Open 60 AAL was created, a 18.30 metre long ocean racing yacht that is used as a demonstrator to prove the robustness, durability and recyclability of the volcanic fibre sandwich composite with a balsa core. For eco-tourism around the shores of Ibiza, the yard developed and built the IY LBV35 catamaran, the world’s first fully recyclable catamaran that generates power for the electric motors and the refrigerator while sailing. Norbert Sedlacek’s efforts to develop sustainable yacht building were honoured in 2023 with the Ocean Tribute Award from the Ocean Foundation of Germany and the Prince Albert II foundation of Monaco. Progressing in their quest towards zero-ecological footprint yachts, the yard presented the Volcat 16 in 2024, built with the next generation of organic fibres: pure mineral fibre.

Aerospace collaboration

Development of new fibres and composites continues. Isomatex developed a new multi-layer textile yarn that can be used in aerospace (and yachting) composites: Application of these niche fibres could get a boostnow that manufacturer Isomatex has issued a joint patent with the helicopter division of aircraft builder Airbus for the Filava/Para Aramid Hybrid Twisted Yarns. The new yarn, basis for woven mats that are infused with resin to create composites, is stronger and has much more impact resistance then carbon fibre, is non-combustible and results in very light weight composites. And it can be recycled and re-used at the end of lifetime, separating the bio-epoxy from the fibres. Need for lightweight and strong composites has surged demand for fossil-based carbon fibre over the last decades. The new mineral hybrid fibre could ease this demand while co-operation with the aeronautical industry could further accelerate composite innovation.

Sustainable charter fleet

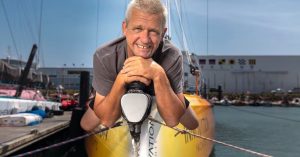

Innovation Yachts plans to start a big upcycling programme, reviving the myriad of abandoned older glass-polyester sailing yachts. A co-operation with Expedition Zero was recently announced. This newly established organisation wants to create a fleet of minimal ecological footprint sailing yachts that can be leased out to enterprises that offer sailing expeditions. Building a fleet of rugged, ocean-capable yachts that are optimised for their energy use and that are built from recyclable materials, Expedition Zero aims to step up the ecological performance of sailing tourism. Expedition Zero is led by a board of experienced leaders in the yachting industry. Andy Hindley gained experience as the operating officer of the America’s Cup organisation and race director of the Volvo Ocean Race. He is now technical advisor at Expedition Zero. “I am thrilled to participate in this project that may transform the maritime industry,’ Hindley expresses. The board is led by long time entrepreneur and start-up advisor Andrew Cowen. He states: “Our ambition is to build a fleet of expedition yachts that reduce the overall environmental footprint of such yachts with 90 percent.” The first yacht to be operational is planned for launch in 2025.

Upcycling refit

Innovation Yachts will prepare the first yacht for Expedition Zero, which will be a total refit of a Challenge 72 ocean expedition sailing yacht. Wherever upgrading or repairs of the composite structure are needed, Filava fibres and bio-based epoxies will be applied. The yacht will be equipped with solar panels, wind turbines and generation of electrical power with propellers in the water, equipped to provide all of the energy needed for household functions aboard the yacht and charge batteries enough to enter harbours with electric propulsion after the multi-day sailing trips. Newbuilds are also on the programme for Expedition Zero, which will then be built with the latest mineral fibre composite technology.