During the 2023 Sydney International Boat Show, Marine Business News was fortunate to be able to sit and chat with David Foulkes, CEO at Brunswick Corporation.

David Foulkes CEO at the Bunswick Corporation

David is described as a product development executive and business innovation leader with a strong record of breakthrough technology development and product success in industry-leading companies. Understandable, given the ongoing announcements and releases from the Mercury Brand, and other products within the Brunswick stable.

Despite his seniority both for Brunswick and our industry, David was highly personable and welcoming in his conversation. His astute understanding of the boating industry, and ability to articulate the Brunswick vision for the business now and into the future, helped me better understand the industry, and overcome the misconceptions I had about the future of electrification.

This is how the conversation went.

Marine Business News – We would love to know and hear your thoughts on the electrification of boating. It has been around for decades in not a very good way, however in the last two to three years we have stepped up to show that our industry is serious. How far is it going to go?

David Foulkes – It’s an interesting question. I think when you compare marine electrification with most commonly things light GT road vehicles which is where electrification is beginning to emerge strongly, there is some similarities but a lot of differences. So light GT road vehicles, passenger cars essentially, I think as electrification technology is developed with batteries with more energy density, high storage capacities, more efficient electric motors, we have begun to see that the overall utility of an electric road vehicle is similar to a combustion engine vehicle.

You can argue that somethings are a little better and that somethings are a little worse. The range is not necessarily quite as long, but the performance is very strong. It’s quieter and obviously the local emissions at least are significantly better.

As you start to look at other applications, even heavy-duty road vehicles, you start to see the electrification journey is going to be a bit longer and a bit more challenging. As soon as you start putting heavy loads on a vehicle, it will start to require more continuous power than a light GT vehicle does, current technology in electrification starts to be challenged.

When I think about marine electrification, I think marine is more like aviation. Boats are very weight sensitive, like aircraft, typically higher continuous power requirements than a passenger car. You might have 400 horsepower in your car, but you are usual only using 40. In a boat you are often at 50% throttle or above, and no brakes to regenerate more energy obviously.

I think the journey for electrification is going to be a bit longer and require more technological evolution to enter mainstream. Nevertheless, there are several applications at the moment that I think are really interesting and useful. One is smaller lower power vessels that we don’t expect a lot of range, or high performance. And that is accelerated by regulatory frameworks particularly in Europe that are beginning to outlaw combustion engines on certain lakes, waterways, and downtown areas and the like.

Quick-Charging Batteries

What has really emerged is a global market of about 50,000 electric outboards below 10 hp. And that is the market that we are entering with the Avator product line, although our product line will extend beyond 10 hp. That’s where the real market is, it is really in Europe, it is really below 10 hp. Current incumbents, Torqeedo, ePropultion, but we thought there was an opportunity to introduce some more technologically advanced solution with more comfort and convenience, features, higher quality, more innovation and that where Avator product line really comes in.

As we get above that smaller boat / lower range, you begin to have to make more compromises particularly on range and performance, but there are still niche applications. Launches, slower boats – so we will be introducing higher power electric applications to satisfy those niches as the technology evolves, those will move from niches to somewhat more core applications. It is still very difficult to foresee that a 200hp conventional engine is going to be replaced in the near future by an electric product. The battery is very heavy, the technology is pretty expensive, so I think it is still niche, but you can still see it moving maybe up into the 50hp range.

The other application I think is really interesting as well, is there is another engine on big boats called a generator. If fact the generator gets used a lot more than the population engines a lot of big boats when you are anchored up for the day.

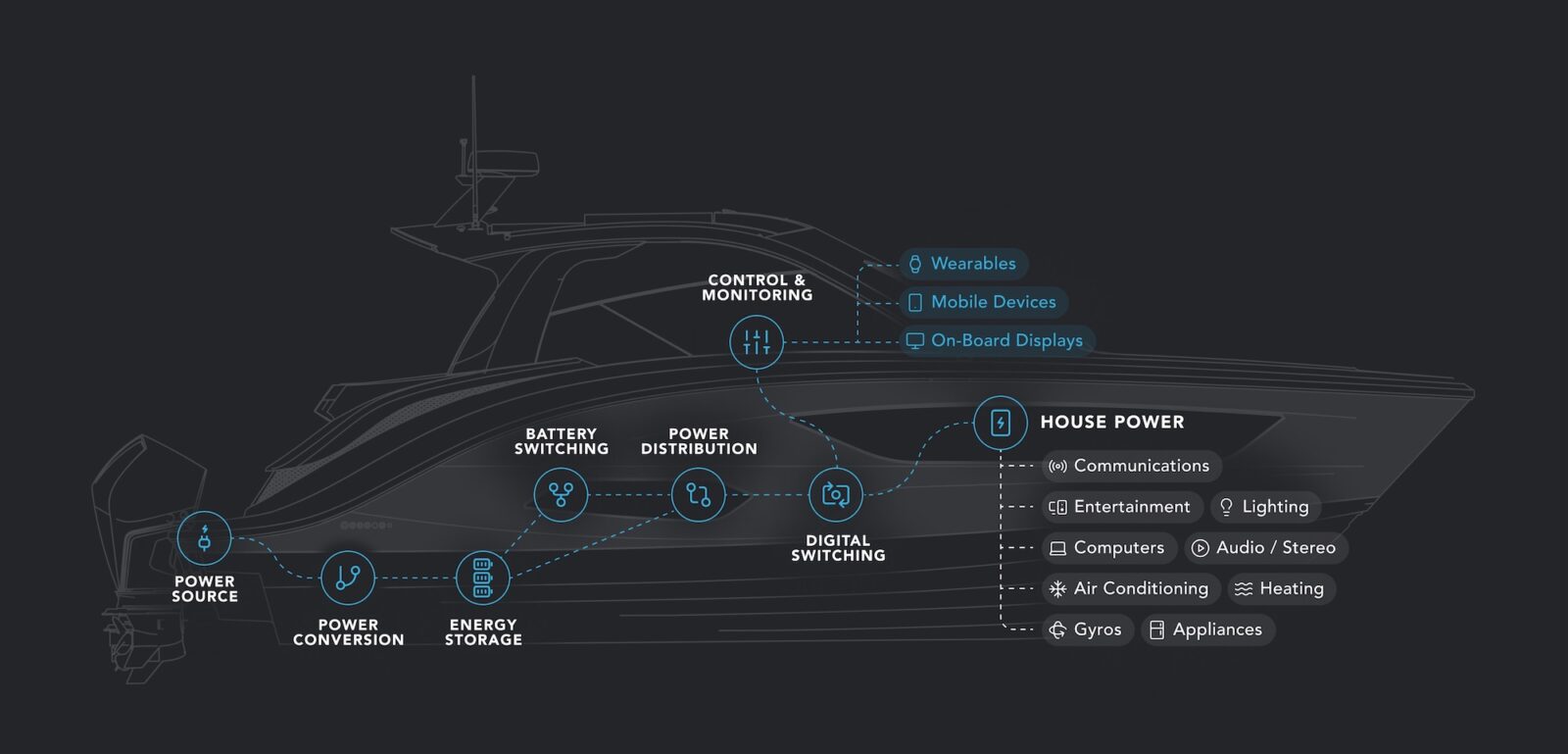

In addition to the Avator product line we have also introduced something called Fathom which is a high capacity lithium-ion battery pack and power distribution system that replaces a generator, and gets recharged from 48 volt alternators on the outboard engines. [/column]

We have launched the V10 and will shortly launch the V12 with 48 volt alternators that rapidly recharge onboard high capacity battery packs that are able to power air-conditioning, other comfort systems, marine electronics and all those things.

Those are the two areas that I think electrification is going to penetrate in the short term. We expect to be in a leadership position with both. We are a leader in conventional propulsion and conventional boat technologies. We expect to be a leader in electrical propulsion and electrification in other areas to.

Marine Business News – I would suggest that the old basics of products are developed and brought to market because of consumer demand, and that is true to a certain degree, but I think what you are saying makes a lot of sense. We can’t begin to think that electric motors will replace the entire portfolio of engines.

David Foulkes – No you can’t

Marine Business News – I’ve seen some of your product downstairs (at the Sydney International Boat Show) your 500R and your 600hp V12. Amazing technology and I have no doubt that there is still a strong demand for that.

David Foulkes – Oh, there’s huge demand, I think the trend towards higher horse power has been present for a number of years and continues to be really strong. I think about 90% of all recreational boats now are sold without outboard power which is very different from 15 or 20 years ago.

When outboards with more than a couple 100 horse power were just not available for big boats, now they are. I think the outboard solution that essentially pulls a couple of big diesels typically out of the engine compartment or bilge and freeze that up for additional useful space. Another bedroom or another something is really attractive to a lot of board manufactures – so that is something we have pushed on.

Back to the electric propulsion thing, in the end the objective is reduce CO2 and improve fuel consumption, which kind of go hand in hand.

Mercury 600hp v12

In additional to electrification, we need to continue to think about how can we improve fuel economy from conventional engines as well since they’re going to be around for a long time in marine.

If you look at the V12, we have the first application of a two-speed transmission, which helps performance and fuel economy. Twin propellers which are more efficient than a single propeller and get a lot of torque to the water. The V12 and all of our engines now have what’s typically called “lean burn” technology. That means optimised combustion with excess oxygen which produces lower emissions. So, in addition to electrification, we’re trying to make all of our conventional product as fuel efficient and low emitting as we possibly can. Which I think is a more important dual path for the future.

Marine Business News – The world is looking at this area very closely. Not only in terms of motors on the water ways but I’ve read that you’ve done some excellent things in your factories to help sustainability and the environment. Tell me about those.

David Foulkes – Yes, there are a lot of things that we can do, and we take very seriously. We published our 3rd corporate sustainability report this year, that documents all of the activities that we have going.

The one you mentioned is really around renewable energy as a source of power for our various facilities. We can do that a couple of ways, more and more we are putting solar rays on our facilities; typically on the roof which is very direct and very helpful. We have done that globally, most recently in out Portugal facility but also in our US facilities and that is in our newest distribution facility too. So that is part of our strategy going forward.

Typically, though, you just don’t have enough roof area to cover all of your energy. So a couple of other things, Mercury Marine is partnering with a local energy provider – Alliant Energy in Wisconsin in the main plant of Wisconsin.

We’re actually building adjointly a solar farm right next to the facility. Which is very exciting, so that’s a new development and the other thing, which is very interesting is we just entered what’s called a ‘virtual power purchase agreement’ (VPPA) which is where you partner with an energy provider, not necessarily local to your facilities but you agree to accept power from this provider and they will build a renewable energy facility – typically solar but also wind farms. So we just entered that VPPA which means, I think by 2030 about 60% of all our plant will be powered by renewable energy sources. We’re working to get to a 100%. It takes a little bit of time to get the infrastructure in place, but it’s clearly the objective.

There are other things that we can do as well in our facilities. We have more and more facilities called “Zero Waste to Landfill” that means we separate our waste streams from that small part that really has to go to a landfill – maybe there’s some chemicals or something in there, and the large majority that can be repurposed and typically we’d say zero waste to landfill if 90-99% of the waste from the facility ends up being recycled in some way or another.

We now – I don’t remember the exact number, but I think we have more than 10 facilities now that satisfy Zero Waste to Landfill. Which is great and the teams are very excited about it.

Then we also recycle water, much more than we used to. If you think about all of the test cells that are running up in our main development site facility in Fond du Lac. We used to have what we called open loop cooling there, so we would take city water to cool the engines and then dump it back out. Now we have a closed circuit, so we reuse to cool and clean the same water multiple times. We have gone from being by far the biggest energy user in the city to a pretty end water user. There is a lot of things we do and continue to pursue.

Marine Business News – Do you foresee that any of these initiatives will have a cost impact on the end product?

David Foulkes – We think it’s a win, win. Normally, things like using less water is beneficial for the environment and also less costly for us. Obviously, typically there’s upfront investment but over time you get lower energy consumption, lower cost of power, lower cost of water and so we do not view it as some kind of dilemma that we have to resolve. I think there’s a way to implement renewable energy sources and recycling in a way that is beneficial from a business perspective as well.

Marine Business News – The pandemic created a challenge for worldwide businesses. Everybody was hurting one way or another. One of the things that was really evident across a lot of industries including our own, was the supply chain issues, where the supply chain issues we’re either unreliable or the quality didn’t continue as it was required. Have you overcome all of the supply chain issues? I ask the question having heard on many instances over the last few days that people are still having them, but they are far better off than they were. How are you?

David Foulkes – Much better off. It was a daily, hourly challenge 18 months to 2 years ago. Across multiple supply chain streams, it is now more back to normal. Even prior to this supply chain crisis, of course you’re always managing supply chain. Suppliers have an interruption or some change or whatever it is. I would say we are much back to normal management of the supply chain with isolates issues verses broad issues.

One of the most recent things that we’ve been doing is increasing production capacity for our high horse power engines so in addition to just going back to steady state requirements, we’ve been increasing the requirements of our supply base because they need to follow us up as our production goes up, all of their supply needs to go up as well. And they have been great partners for us as we have worked through that. I would say even beyond getting back to steady state, we are now in a position where supply chain partners can reaccelerate and meet our increasing production demands for high horse power outboard in particular.

Marine Business News – The other phenomenon that we all faced was a disappearing workforce, all of a sudden workforces disappeared, we lost our skill set, and then what we found was that the returning workforce wanted more money, more challenging work conditions – ‘I want to work from home’ a big thing. How did you face those issues?

The question I ask is where did the workforce go around the world? People were saying to me, a lot of the people that were travelling to Australia for work, found work in their own countries, because their local staff was disappearing.

Where did the workforce go? How did you find things?

David Foulkes – Certainly after the worst of Covid, that was in a little bit of a different time around the world as the various countries processes around Covid freed up, I think we clearly had to make huge efforts to bring our workforce back and it was an effort that required some creativity.

We had to attract people in different ways, we had to source labour from areas that were more remote from our facilities. We went through a very systematic process for every facility. First of all being an employer of choice, if you’re not an employer of choice – that’s tough.

When I say employer of choice, there’s an annual report that comes out ‘US News and World Reports’ and Forbes and other magazines publish the best employers. Brunswick is frequently featured on those lists as a best employer. So recently, US News and World Reports featured Brunswick in its list of best employers in the US and we were in the top 10 of all companies in the US for quality of pay, that means the type of compensation we provide beyond just wages, through medical benefits, various support pension or retirement planning – all of those things. We have a very competitive total compensation plan.

We have a really strong culture; I think a really attractive culture to work in. We’re not a bang the table, scream and shout culture, we’re a very collaborative culture. I think we’re a very inclusive culture.

I think we’ve made all of our businesses a really attractive places to work, never the less, you have to work hard to get who you want. I think our talent and recruitment teams did an extraordinary effort with marketing and advertising and everything depends locally on the situation. But we’re through it all now, I think we have a really strong situation for employment, with very high-quality employees.

Marine Business News – Just one last question, I am interested in the future, and how you see it and in particularly I’m keen to know if you feel that artificial intelligence will play a role in making the boating lifestyle that little bit better?

David Foulkes – Yes, I think it will play a role in a lot of aspects our lives, I think because of recent publicity around ChatGPT and some of the other AI engines that have come to the fore recently, the real fact is that AI has been developing in part of our lives for a long time. Every time you speak to Siri on your iPhone, she gets smarter.

I don’t think it’s quiet such a step function as some recent reports have suggested. But what is very interesting and we’re certainly perusing is a whole range of possibilities of applications of AI.

You can easily think about AI as a customer support tool ‘there’s something wrong on my boat, help me understand what it is?’ – a diagnostic process or an information generation process ‘find me the nearest fantastic anchorage in my area’ you can certainly think about that.

We’re developing a lot of autonomous functions – autodocking and other things that certainly benefit from various aspects of AI and I think there are a lot of creative applications of AI that are really interesting.

One of our design team shared with me the other day, they had input some of the key design DNA elements of one of our boat brands and the AI tool had generated boat designs – which is very cool. The boat designs are not useable out of the AI generator but in terms of generating a landscape of possibilities, it’s incredibly useful and then we can pick from those and refine them and do all those kinds of things.So I love the potential of AI to make everybody’s life a little bit better certainly the complexity of current boats, making it more intuitive to use, to diagnose, to making boating destinations more easy to understand, making routine manoeuvres easier, how do I anchor – that kind of stuff.

I think there are super opportunities there.

Marine Business News – David – we thank you for your time.

Domenic Genua, Publisher of Marine Business News with David Foulkes CEO at the Bunswick Corporation.

This interview took place in Sydney, Australia, on August 4, 2023, whilst David was in town for the Sydney International Boat Show.

Domenic Genua, the Owner & Publisher of Marine Business News, conducted the interview.

Marine Business News extends its heartfelt appreciation to David Foulkes for generously dedicating his time to us.

To keep up to date with all marine industry news visit www.marinebusinessnews.com.au