An ongoing commitment to quality and innovation is synonymous with Riviera and partnering with industry-leading suppliers who share our passion for excellence has allowed us to create a range of magnificent luxury motor yachts that continue to evolve.

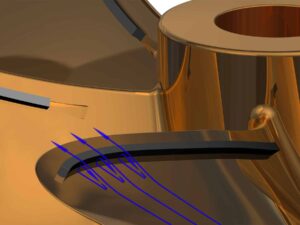

VEEM C-Star propellers undergoing evaluation in a cavitation testing tunnel showing the formation of stable sheet cavitation on the low-pressure side of the blade.

Over the past 16 years Riviera has developed a strong partnership with West Australian propeller manufacturer, VEEM, and our owners are enjoying the benefits with a quiet, smooth ride.

Propspeed is applied to VEEM C-Star propellers as a factory inclusion for all new Riviera yachts and is recommended for existing yachts as protection against fouling and corrosion of running gear.

Riviera started fitting VEEM propellers in 2006 in order to ensure the smoothest possible performance with shaft drive systems. Today all shaft-driven Riviera luxury motor yachts from the 64, 68 and 72 Sports Motor Yachts through to the 78 Motor Yacht are fitted with VEEM CNC machined propellers that feature the VEEM Interceptor™ technology.

The Riviera 78 Motor Yacht is one of many larger Riviera luxury motor yachts to take full advantage of VEEM propellers which offer the smoothest possible performance.

In order to gain a better understanding of why Riviera employ VEEM C-Star propellers and why they are superior in performance, Experience magazine spoke with Dan Henderson, Riviera’s Design & Engineering Director and Brad Miocevich, Chairman of VEEM Ltd.

“VEEM was the only supplier that we found who did what they said in terms of achieving the correct pitch, the correct balance, controlling vibration and not just on one specification but repeatedly; time after time. Their manufacturing process uses all CNC (Computer Numerical Control) machine technology to ensure the propellers are fully CNC’d and measured, and they take all the possible variables into account,” Henderson says.

VEEM’s patented Interceptor™ strip fits into a dovetail groove which has a special entry area near the root of each blade. The complex groove geometry can only be created using the very latest high-speed contouring 5 axis CNC machines.

Pitching the Propeller

“The reason we use VEEM is due to its adjustability. The technology allows us to pitch the propeller correctly during the build phase. Correctly pitched means it’s able to achieve a certain RPM, this is normally 50 RPM above the rated RPM of the engine,” he adds.

Previously, if modifications were made to a yacht’s specification the weight may vary therefore the propellers would have to be re-pitched off site.

“A VEEM propeller is finely tuned, CNC machined and manually reworking it could put it out of balance both statically and dynamically. Not just in terms of the weight but also the shape of the blade. There are five different blades and they need to be perfectly aligned or there will be some vibration. The key reason we use VEEM is to control and reduce any vibration.”

The entire propeller surface is CNC machined to ensure every propeller delivered is exactly as the engineering team designed it

The Interceptor™ strip comes in different heights. By changing the height of these strips, the flow of water across the pressure face of the propeller blade is deflected, resulting in a change to the effective pitch of the blade

Technical Innovation

VEEM’s patented Interceptor™ technology allows propellers to be effectively re-pitched without lifting the vessel. A diver can replace the slide-in interceptor strips in minutes, to adjust for variations in vessel displacement, water temperature, hull fouling condition, or even the required operational profile.

“The removable plastic strips run on the trailing edge of the propeller act like an interceptor trim tab on a boat. The pitch can be decreased or increased by making the plastic lip taller or shorter.”

Henderson says it’s just like changing gears in a car. If a certain speed is required, a certain RPM, and it’s in third gear and not right, a change up to fourth will achieve the speed and optimal fuel economy.

“VEEM are very good engineers. They’re factual and very clever people who have done a lot of research and development and hard work to produce a superior product. The Interceptor™ technology is ground-breaking and I think it’s amazing that an Australian company developed it and is leading the way.”

The Interceptor™ strip can be easily removed when required

Precision and Practicality

However, the question remains, “Do you really need to change the pitch of your propeller?” According to Henderson, most Riviera owners just want to set and forget.

“If an owner wants to run around with only half the fuel and half the load compared to a fully loaded motor yacht, they are able to do that by putting slightly larger strips on the propeller and having a boat that is faster.”

“The real advantages from an owner’s perspective is not just minimised vibration, but also speed. That’s the main thing people look for in propellers. Our owners want to ensure they get good speed out of their motor yacht. The VEEM C-Star is designed for speed and we’re very happy with their performance.”

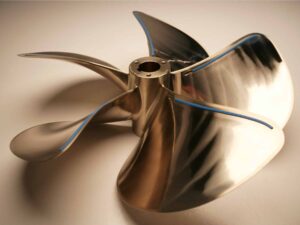

VEEM C-Star Interceptor™ propellers include a high lustre finish

Closer detail of the CNC machined propeller surface of the VEEM C-Star Interceptor™ propeller

Seamless CNC Manufacturing

One of the competitive advantages of the Riviera/VEEM partnership, is having more control over the manufacturing process and supply chain.

“We operate differently from a manufacturers’ perspective because at VEEM we control the process as everything moves straight from the foundry to the CNC machines. Taking control of that supply chain process reduces delays which is a major advantage,” says VEEM Chairman, Brad Miocevich.

“A big takeaway of when we first started working with Dan Henderson and the Riviera design team was that as we developed new technology the engineering teams could all talk the same language. Our ongoing research and technology benefits Riviera as they design new models,” Miocevich adds.

For Dan Henderson the highlight of working with VEEM was when the initial tests were first conducted and he saw the interceptor strip. He realised he was dealing with a company that not only had a quality product but delivered on their word.

“They’re exceptionally accurate, very repeatable and extremely well-balanced propellers. Together with the changeable interceptor strip, nothing else comes close,” Henderson concludes.

For more information visit www.rivieraaustralia.com