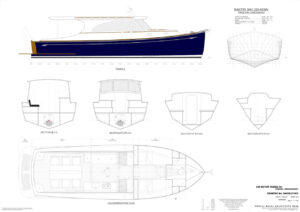

The latest Dovell-designed motor yacht is a charming 32-foot day boat called ELEKTRA, with the hospitable characteristics to enhance a pleasant day on the Harbour with family and friends.

The client, whose family owns several seafood restaurants, envisaged the 32-foot vessel, named “Elektra”, as a versatile picnic boat for celebrating “the joys of life, good food, great friends, beautiful scenery”.

Constructed by Innovation Composites in Nowra on the NSW South Coast, “Elektra” will soon take to its home waters of Sydney Harbour, with the occasional voyage to Pittwater.

Innovation Composites Director, Mark Rowed heads up the build and has worked on several Dovell-designed projects over the past 30 years.

Based on the precursor, a 32-footer named “Stormy Weather”, the design took shape from the client’s specific brief.

As Andrew Dovell explains, “It was designed as a modern version of the traditional down-east lobster boat, with a sizeable cockpit with a table for six to eight guests as the central focus.

“The client wanted a boat that would be a multi-generational day boat, enough room for two to four guests to sleep overnight, and a nice flat roof for the grandkids to jump off into the water.”

Inside, the compact galley is more a servery with an open, free flow from the cockpit for a truly social space, and the settee converts to a double bed. There are two additional pilot berths forward, and a bathroom.

“This style of boat flairs in such a way as to give you a lot of shoulder room, not a lot of floorspace. The cockpit makes up close to half the boat. That’s what it’s all about – enjoying a day out on the water with delicious food.

“In preliminary designs, the roof only came halfway back, but we decided to extend the roofline because we’ve all had enough sun by mid-morning.”

The boat is built of strip-planked, Australian-grown Paulonia over plywood frames. ATL Composites’ Kinetix R246 TX laminating resin with H160 Hardener was specified for sheathing the hull shell inside and out, as well as internal taping of bulkheads and stringers.

Kinetix R246 cures at room temperature, or low elevated temperature, and is suitable for fibre composite construction. The low viscosity of this system is a significant aid in both hand lamination, or machine impregnation, operations.

The relatively low activity of R246 offers extended working times which is also a benefit for large laminating projects.

Also from ATL, Techniglue R60, a Marine and Timber industry favourite, was chosen for general gluing of timber, as well as for bonding the teak decking and Technifill XP pre-blended fairing compound from ATL was applied to produce a smooth, easy to sand base for the final paint finish.

“We wanted to achieve the timber feel through water, without the maintenance of a wooden boat,” Andrew explains.

“To be able to maintain a timber boat like a composite in this size is gold!”

The teak decks have been left raw, further reducing maintenance, and the only bright work (varnished timber) is on the interior.

Mark says Kinetix R246 was his resin of choice. “We had used it before and found it to be very user friendly and also very well priced. We’ve used ATL Composite products for many years. We never have issues and their technical support is always on hand for advice.”

https://www.dovellnavalarchitects.com.au/

http://www.innovationcomposites.com.au/